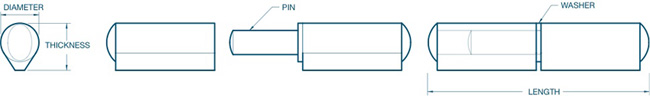

Mild Steel with Fixed Steel Pin, Brass Bushing

FEATURES

FEATURES Flexible installation solution for overlapping doors/panels with limited space, and flush doors.

Parts are specially buffed and are free of burrs, allowing for improved paint adherence.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact NMT for further assistance.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact NMT for further assistance.

Open Tab for Product Break Down (Mild Steel with Fixed Steel Pin, Brass Bushing)

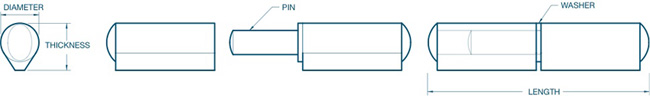

| Mild Steel with Fixed Steel Pin, Brass Bushing | ||||||||

| Part # | Length | Thickness | Diameter | Pin Diameter | Drawings | CAD | ||

| PS40SP | 1.575 | 0.374 | 0.315 | 0.197 | [PDF] | [.stp] | ||

| PS50SP | 1.969 | 0.394 | 0.315 | 0.197 | [PDF] | [.stp] | ||

| PS60SP | 2.362 | 0.472 | 0.394 | 0.236 | [PDF] | [.stp] | ||

| PS70SP | 2.756 | 0.512 | 0.453 | 0.236 | [PDF] | [.stp] | ||

| PS80SP | 3.150 | 0.610 | 0.512 | 0.315 | [PDF] | [.stp] | ||

| PS90SP | 3.543 | 0.610 | 0.512 | 0.315 | [PDF] | [.stp] | ||

| PS100SPGF | 3.937 | 0.768 | 0.630 | 0.394 | [PDF] | [.stp] | ||

| PS100SP | 3.937 | 0.768 | 0.630 | 0.394 | [PDF] | [.stp] | ||

| PS120SP | 4.724 | 0.787 | 0.630 | 0.433 | [PDF] | [.stp] | ||

| PS135SP | 5.315 | 0.906 | 0.709 | 0.512 | [PDF] | [.stp] | ||

| PS150SPGF | 5.906 | 0.984 | 0.787 | 0.512 | [PDF] | [.stp] | ||

| PS150SP | 5.906 | 0.984 | 0.787 | 0.512 | [PDF] | [.stp] | ||

| PS180SP | 7.087 | 0.984 | 0.787 | 0.512 | [PDF] | [.stp] | ||

| PS200SPGF | 7.874 | 1.122 | 0.906 | 0.630 | [PDF] | [.stp] | ||

| PS200SP | 7.874 | 1.122 | 0.906 | 0.630 | [PDF] | [.stp] | ||

| PS260SP | 10.236 | 1.457 | 1.102 | 0.748 | [PDF] | [.stp] | ||

| PS260SPGF | 10.236 | 1.457 | 1.102 | 0.748 | [PDF] | [.stp] | ||

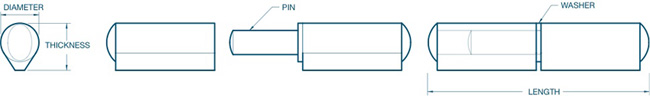

304 Stainless Steel with Fixed Stainless Steel Pin and Bushing

FEATURES

FEATURES Flexible installation solution for overlapping doors/panels with limited space, and flush doors.

Parts are specially buffed and are free of burrs, allowing for improved paint adherence.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact Normont for further assistance.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact Normont for further assistance.

Open Tab for Product Break Down (304 Stainless Steel with Fixed Stainless Steel Pin and Bushing)

| 304 Stainless Steel with Fixed Stainless Steel Pin and Bushing | ||||||||

| Part # | Length | Thickness | Diameter | Pin Diameter | Drawings | CAD | ||

| SS40SS | 1.575 | 0.374 | 0.315 | 0.197 | [PDF] | [.stp] | ||

| SS50SS | 1.969 | 0.394 | 0.315 | 0.197 | [PDF] | [.stp] | ||

| SS60SS | 2.362 | 0.472 | 0.394 | 0.236 | [PDF] | [.stp] | ||

| SS70SS | 2.756 | 0.512 | 0.453 | 0.236 | [PDF] | [.stp] | ||

| SS80SS | 3.150 | 0.610 | 0.512 | 0.315 | [PDF] | [.stp] | ||

| SS100SS | 3.937 | 0.768 | 0.630 | 0.394 | [PDF] | [.stp] | ||

| SS135SS | 5.315 | 0.906 | 0.709 | 0.512 | [PDF] | [.stp] | ||

| SS150SS | 5.906 | 0.984 | 0.787 | 0.512 | [PDF] | [.stp] | ||

| SS200SS | 7.874 | 1.122 | 0.906 | 0.630 | [PDF] | [.stp] | ||

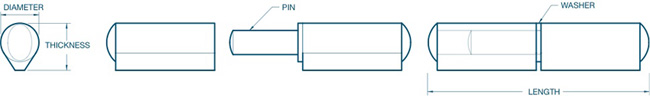

Mild Steel with Fixed Brass Pin, Brass Bushing

FEATURES

FEATURES Flexible installation solution for overlapping doors/panels with limited space, and flush doors.

Parts are specially buffed and are free of burrs, allowing for improved paint adherence.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact Normont for further assistance.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact Normont for further assistance.

Open Tab for Product Break Down (Mild Steel with Fixed Brass Pin, Brass Bushing)

| Mild Steel with Fixed Brass Pin, Brass Bushing | ||||||||

| Part # | Length | Thickness | Diameter | Pin Diameter | Drawings | CAD | ||

| PS40BP | 1.575 | 0.374 | 0.315 | 0.197 | [PDF] | [.stp] | ||

| PS50BP | 1.969 | 0.394 | 0.315 | 0.197 | [PDF] | [.stp] | ||

| PS60BP | 2.362 | 0.472 | 0.394 | 0.236 | [PDF] | [.stp] | ||

| PS70BP | 2.756 | 0.512 | 0.453 | 0.236 | [PDF] | [.stp] | ||

| PS80BP | 3.150 | 0.610 | 0.512 | 0.315 | [PDF] | [.stp] | ||

| PS90BP | 3.543 | 0.610 | 0.512 | 0.315 | [PDF] | [.stp] | ||

| PS100BP | 3.937 | 0.768 | 0.630 | 0.394 | [PDF] | [.stp] | ||

| PS120BP | 4.724 | 0.787 | 0.630 | 0.433 | [PDF] | [.stp] | ||

| PS135BP | 5.315 | 0.906 | 0.709 | 0.512 | [PDF] | [.stp] | ||

| PS150BP | 5.906 | 0.984 | 0.787 | 0.512 | [PDF] | [.stp] | ||

| PS180BP | 7.087 | 0.984 | 0.787 | 0.512 | [PDF] | [.stp] | ||

| PS200BP | 7.874 | 1.122 | 0.906 | 0.630 | [PDF] | [.stp] | ||

| PS260BP | 10.236 | 1.457 | 1.102 | 0.748 | [PDF] | [.stp] | ||

Aluminum with Fixed Stainless Steel Pin and Bushing

FEATURES

FEATURES Flexible installation solution for overlapping doors/panels with limited space, and flush doors.

Parts are specially buffed and are free of burrs, allowing for improved paint adherence.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact Normont for further assistance.

Built-to-print solutions are available.

Component replacement parts are available.

Standard weld-on hinges have rounded ends, if flat ends are required, please specify FE (flat ends) at the end of the part number.

For grease fittings, please specify GF (grease fittings) at the end of the part number. Available from 80 mm to 200 mm.

Installation: Ensure the hinge is welded along the full length of the weld tab.

Caution: During the welding process (installing the hinge to the door/panel), ensure the weld does not penetrate through the wall of the female barrel. If this occurs, the pin will be welded to the barrel, thus causing the hinge to cease. The hinge will not be able to rotate. The hinge will have to be replaced. Contact Normont for further assistance.

Open Tab for Product Break Down ( Aluminum with Fixed Stainless Steel Pin and Bushing)